Click here to download the instruction manual

Click here to download the settings

▌ Attention!

-

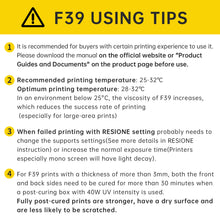

This resin is not recommended for novice users. Please download the manual before use.

-

When failed printing with RESIONE setting probably needs to change the supports settings(See more details in RESIONE instruction) or increase the normal exposure time(Printers especially mono screen will have light decay).

-

Flexible prints are easily deformed during printing, so they need thicker and denser supports.

-

If the ambient temperature is lower than 25℃, please preheat the resin liquid before printing. And the print will lose its flexibility as the temperature drops.

-

For F69 prints with a thickness of more than 3mm, both the front and back sides need to be cured for more than 30 minutes when a post-curing box with 40W UV intensity is used. Fully post-cured prints are stronger, have a dry surface and are less likely to be scratched.

-

If you need a softer and faster rebound resin, please choose F80 resin.

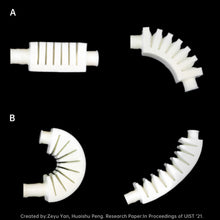

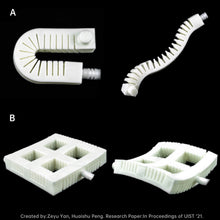

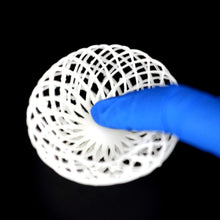

F39 resin is a white flexible resin with a high printing success rate. This resin is designed to provide prints with outstanding tear strength and flexibility. It finds wide application in figure toys such as dolls' vests, capes, weapons, and footwear, tires, shoe samples, seals, buffers, gaskets, transmission belts, and various flexible prototype production. Additionally, mixing F39 with other resins can enhance the non-brittleness of printed parts.

▌ Descriptions

-

Like rubber: Flexible, tear resistance, folding resistance

-

Easy-to-use soft resin

The release agent is added to its formula, so after each exposure, the curing layer will have less adhesive force when it leaves the FEP film. In addition, the RESIONE team has specially designed the formula to ensure that the printed part exhibits a "soft with rigidity" performance during the printing process, ensuring that it does not deform.

-

As toughening agent

Mixing F69/F39/F39T resin with tough resin such as K/M58/M68/G217 can make the printed parts tougher, more durable, and not brittle for a long time.

-

Wide application

Flexible resin is widely used in figure toys, footwear, design and industrial fields, such as tires, shoe samples, seals, gaskets, transmission belts, various flexible prototypes and dolls' vests, capes, weapons, etc.

-

Detailed print settings and user's guide

We provide settings for almost all mainstream 3D printers, and include importable settings files for different slicers, such as Chitubox/Lychee/Anycubic Workshop, etc. We also provide detailed instructions for the use of the resin and supports settings suitable for flexible resin.

▌ Reviews

- Youtube:Andrew Sink

- FabHydro: Printing Interactive Hydraulic Devices with an Affordable SLA 3D Printer

▌ Certification

▌ Compatible 3D Printer

-

All series of Anycubic,Elegoo,Nova3d,Peopoly,Phrozen,Epax,Creality,Zortrax, BIQU, QIDI, UNIZ, Flashforge, Voxelab, Longer, Uniformation etc. UV 395-410nm LCD resin 3D printer

-

All series of Anycubic,Asiga, Solus series, Miicraft, Kudo3d, Flashforge,Makex,Shining etc. UV 385-410nm DLP resin 3D printer

| METHOD | DATA | |

| Shore Hardness | ASTM: D2240-05 | 60~75A |

| Tear strength | ASMT: D624-98 | 47.2KN/m |

| Tensile Strength | ASTM: D412-06 | 7.9MPa |

| Elastic Modulus | ASTM: D412-06 | 2.0MPa |

| Elongation at Break | ASTM: D412-06 | 255.1% |

| Viscosity(25℃) | ASTM: D4212-10 | 1250mpa.s |

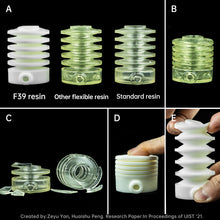

▌ The difference between F39, F69, F39T and F80

- Color:F39 is white, F69 is black, F39T is transparent,F80 is gum color

- Elasticity: F80 > F39 = F69 = F39T

- Tear strength: F80<F39 = F69 = F39T

- F80 prints can remain soft at low temperatures, others will become hard