Click here to download the instruction manual

Click here to download the settings

Anti-Impact Black has arrived at the US warehouse and is expected to reach the German warehouse by the end of July.

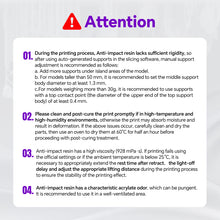

The newly launched black Anti-Impact has mechanical properties similar to the white gray versions, but offers better accuracy and surface finish. However, for the same model, the black version requires thicker support tips compared to the white gray ones. In addition, the black version requires a longer curing time.

-

Anti-impact resin liquid has the characteristic smell of acrylate, which is quite pungent. It is recommended to use it in a ventilated environment or on a 3d printer with an air purifier.

-

Anti-impact liquid viscosity is relatively high (25 ℃/77 ℉, 700mpa. s), and the stiffness of thin wall or thin diameter structure is not enough, so the printing difficulty is higher than that of standard/rigid resin.

-

Prints will become soft and weak under the following conditions: liquids are stored unsealed after long-term exposure to air (especially in the environment with high humidity); Clean with solvent or ultrasonic for more than 5 minutes. The solution when the prints becomes soft is to place them in thermostatic drying oven at 60-80 ℃ (140-176 ℉) for 30 minutes before post curing. The prints will become harder and more stable.

▌ Reviews

- Youtube: How I mix Resins for my Action Figure 3D Prints | Azrach Toys

- Youtube: M58 & Anti Impact--Nathan Kozuch

- 3D Print BJD Wear Resistant Joints--Helene Holz (Youtube)

- Youtube: RESIONE アンチインパクトレジンは耐衝撃性・靭性・耐摩耗性が優秀 | それつくちゃんねる / SoreTsuku

▌ Descriptions

-

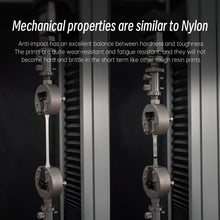

High impact strength and tensile toughness

-

Mechanical properties are similar to nylon and stable for a long time

-

Low water absorption, low temperature resistance, good weatherability

-

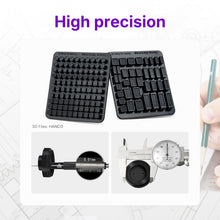

High dimensional accuracy, fine and wear-resistant surface

Anti-impact prints can meet the tolerance requirements of the outer diameter and aperture of the same printed part at the same time, with high dimensional accuracy. And the special formula makes the printing surface smooth and delicate, wear-resistant and scratch resistant.

- Special smell, and not suitable for novices

Anti-impact resin liquid has the characteristic smell of acrylate, which is quite pungent. Anti-impact liquid viscosity is relatively high (25 ℃/77 ℉, 700mpa. s), and the stiffness of thin wall or thin diameter structure is not enough, so the printing difficulty is higher than that of standard/rigid resin.

▌ Cleaning and Post-curing

- Cleaning time: ≤5mins

- Cleaning solvent: 95% Ethanol or IPA

- Post-curing light source: 385-405nm UV(40W)

- Post-curing time: 15mins

▌ Compatible 3D Printer

-

All series of Anycubic,Elegoo,Nova3d,Peopoly,Phrozen,Epax,Creality,Zortrax, BIQU, QIDI, UNIZ, Flashforge, Voxelab, Longer, Uniformation etc. UV 385-410nm LCD resin 3D printer

-

All series of Anycubic,Asiga, Solus series, Miicraft, Kudo3d, Flashforge,Makex,Shining etc. UV 385-410nm DLP resin 3D printer

▌ Material performance parameters

| METHOD | White- Gray | Black | |

| Viscosity(25℃)(mpa.s) | ASTM:D4212-10 | 928 | 609 |

| Liquid density(g/cm³) | ASTM:D4052-22 | 1.075 | 1.07 |

| Solid density(g/cm³) | ASTM:D792-20 | 1.137 | 1.105 |

| Shore Hardness(D) | ASTM:D2240-05 | 79 | 73 |

| Tensile Strength(MPa) | ASTM: D638-14 | 27 | 26.8 |

| Tensile Modulus(MPa) | ASTM: D638-14 | 756 | 910 |

| Elongation at Break | ASTM: D638-14 | 93.00% | 94.70% |

| Flexural Strength(MPa) | ASTM: D790-10 | 34 | 27 |

| Flexural Modulus(MPa) | ASTM: D790-10 | 1098 | 760 |

| Notched IZOD(J/m) | ASTM:D256-10 | 55.9 | 67-75 |

| Water Absorption(24hr) | ASTM:D570-22 | 0.45% | 0.42% |