Click here to download the instruction manual

Click here to download the settings

How to Post-Process Water-Washable Resin Prints the Right Way

TH-WW is a water-washable resin with excellent toughness, featuring crack resistance, low deformation, wear resistance, and fine detail reproduction. It is ideal for creating finely detailed miniatures and transparent anime effect parts.

▌ Key Features

Water-washable, Excellent toughness, Non-greasy&Non-whitening, Long-term crack-resistant, Low deformation, High-detail accuracy, Wear-resistant (non-transparent colors), Anti-yellowing, Low odor, SVHC compliant

▌ Descriptions

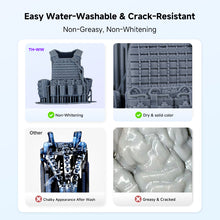

Easy Water-Washable, Non-Greasy, Non-Whitening, and Crack-Resistant:

TH-WW's formula dissolves easily in water, greatly improving cleaning efficiency and experience compared to previous products. Printed parts are easily washed clean with water, and after cleaning, the surface remains dry and non-whitening. Unlike other water-washable resins, it is not prone to cracking due to changes in environmental conditions.

Outstanding Impact Toughness:

TH-WW boasts excellent impact resistance, allowing printed miniatures to withstand accidental drops, post-processing operations, daily handling, and transport bumps without damage. It offers great durability.

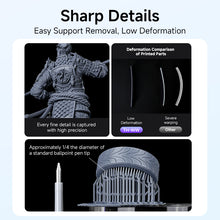

Fine Details, Wear-Resistant, and Anti-Yellowing:

TH-WW delivers exceptional detail accuracy. The carefully designed mechanical properties make support removal easy, and lightweight models support ultra-fine 0.15mm support points. The non-transparent color series of printed parts won't easily generate powder during friction, while the transparent color series is resistant to yellowing. This makes it ideal for printing finely detailed miniatures, GK, transparent anime effect parts, and other models that require high color stability.

Low Deformation:

Through long-term comparative testing, TH-WW printed parts do not exhibit significant deformation over time, making it an ideal material for printing slender weapon accessories, wings, plate armor, and other flat components.

Low Odor, SVHC Compliant:

TH-WW releases no irritating odors during printing and cleaning, greatly enhancing the user experience. The raw materials have passed screening for over 250 substances of very high concern (SVHC) in compliance with the EU REACH regulation. With proper ventilation, it can be used with peace of mind in home or small studio environments.

▌ Printing Settings

Operating Temp: 25~35℃/77~95℉

Layer Height: 0.05mm/0.03mm

Exposure Time: 2.6~3.9s/1.8~2.7s

Bottom Exposure Time: 40~60s

Lifting Height:

LCD Screen size less than 8.9 inches: 7mm

LCD Screen size ≥8.9 inches: ≥9mm

Rest Time After Retract/Off times /Light-off Delay: ≥3s

▌ Cleaning and Post-curing

Support Removal

Cleaning

Clean with tap water at least twice, and the total soaking time should not exceed 5 minutes.

Drying the prints

Use a compressed air tool or high-speed hair dryer to dry the printed part, ensuring no residual water droplets or resin are left.

Post-Curing

For example, using the Anycubic Wash Plus curing station (light intensity 3.6-23 mW/cm²), cure both sides of the printed part for 10 minutes each.

▌ Attention

1.After complete curing, the printed part will still retain some flexibility (especially for thin-walled or delicate structures). It is not necessary to over-cure the model — simply follow the official post-curing guidelines and ensure the surface is dry.

2.Immediately after post-curing, resin prints will have low strength and be in a fragile state. It is not recommended to apply force to the printed part at this stage. It is recommended to wait for some time to allow the part to cool naturally, releasing internal stress and ensuring the part regains its proper mechanical properties.

★3.This resin (non-transparent colors) tends to settle easily. Please shake it thoroughly before use. In cold winter conditions, warm it up to 60 °C before shaking. Resin in the vat can be stirred well using a silicone spatula.

4.For hollow structure prints, ensure that the interior is thoroughly cleaned, dried, and fully post-cured.

★5.When cleaning printed parts, avoid rubbing or scrubbing by hand to prevent parts from colliding with each other in the cleaning machine, as this could result in poor surface quality.

▌ Compatible 3D Printer

-

All series of Anycubic,Elegoo,Nova3d,Peopoly,Phrozen,Epax,Creality,Zortrax, BIQU, QIDI, UNIZ, Flashforge, Voxelab, Longer, Uniformation etc. UV 385-410nm LCD resin 3D printer

-

All series of Anycubic,Asiga, Elegoo, Solus series, Miicraft, Kudo3d, Flashforge,Makex,Shining etc. UV 385-410nm DLP resin 3D printer

▌ Material performance parameters

| METHOD | DATA | |

| Viscosity(25℃)(mpa.s) | ASTM:D4212-10 | 800 |

| Liquid density(g/cm³) | ASTM:D4052-22 | 1.131 |

| Solid density(g/cm³) | ASTM:D792-20 | 1.215 |

| Shore Hardness(D) | ASTM:D2240-05 | 70 |

| Tensile Strength(MPa) | ASTM: D638-14 | 17.38 |

| Tensile Modulus(MPa) | ASTM: D638-14 | 446 |

| Elongation at Break | ASTM: D638-14 | 24.18% |

| Flexural Strength(MPa) | ASTM: D790-10 | 19.4 |

| Flexural Modulus(MPa) | ASTM: D790-10 | 670 |

| Notched IZOD(J/m) | ASTM:D256-10 | 28.9 |

| Water Absorption(24hr) | ASTM:D570-22 | 16.70% |